Let The Metal Atoms Fly… CVD nickel foam Mond

- Metals such as nickel and iron can be transferred to vapor-phase organometallics and refined at low temperatures through the carbonylation process (the Mond process). Read more in these Wikipedia articles.

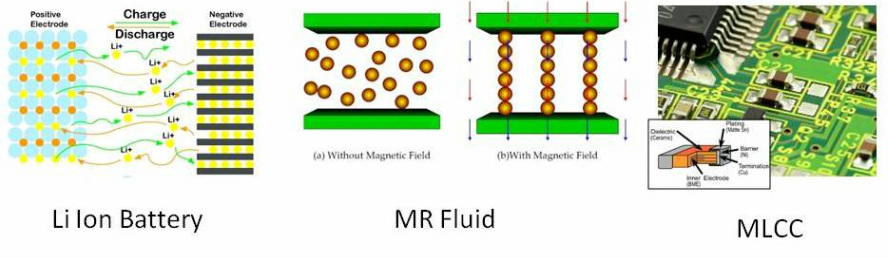

Pathways for Practical High-Energy Long-Cycling Lithium Metal Batteries

- A Nature Energy Perspective was published by 20 leading experts in lithium-ion batteries This included Nobel Laureates Profs. John Goodenough and Stanley Whittingham. Read the important solutions proposed in the literature to characterize and mitigate Li metal problems from Nature Energy Article.

MR Fluid Technology Improves Our Daily Life

- Magnetorheological (MR) fluid technology was a great invention by Dr. Dave Carlson. He wrote a famous article “Dr. Dave’s Do-It-Yourself MR Fluid”. Check various products with MR fluid technology from Lord Corporation.

There Are Over 300 MLCC Chips Inside a Smart Phone. How are they made with ultrafine Ni and Cu powders?

- MLCC stands for Multilayer Ceramic Capacitors, a device consisting of electrode layers made with ultrafine nickel powder, ceramic dielectric layers and terminations containing ultrafine copper powder. This article explains more about ceramic capacitors.

Preferred Electrode Material for HEV Battery: Nickel Foam CVD Mond Process

- Nickel foam made by the carbonyl CVD process can prevent harmful contamination such as copper in the HEV battery electrodes for improved battery life. For more information, see article1 and article 2.

NSERC Discovery Frontiers Project

- This project is the Canadian government’s initiative of investment in areas critical to the country’s economy. 2016 Discovery Frontiers Project focuses on clean tech related energy projects led by Queen’s University. Cnem was invited as an industry partner of the 2016 NSERC Discovery Frontiers Project.

Metal Foams: A Design Guide

- By Dr. M.F. Ashby et al. Metal foams are at the forefront of technological development for the automotive, aerospace, and other weight – dependent industries. They are formed by various production methods and provide a unique, 3-dimensional conductive network with porosities up to the high 90% range.

You can contact us regarding any further inquiries and information on the products we carry, as well as all the services we offer at Cnem Corporation

,